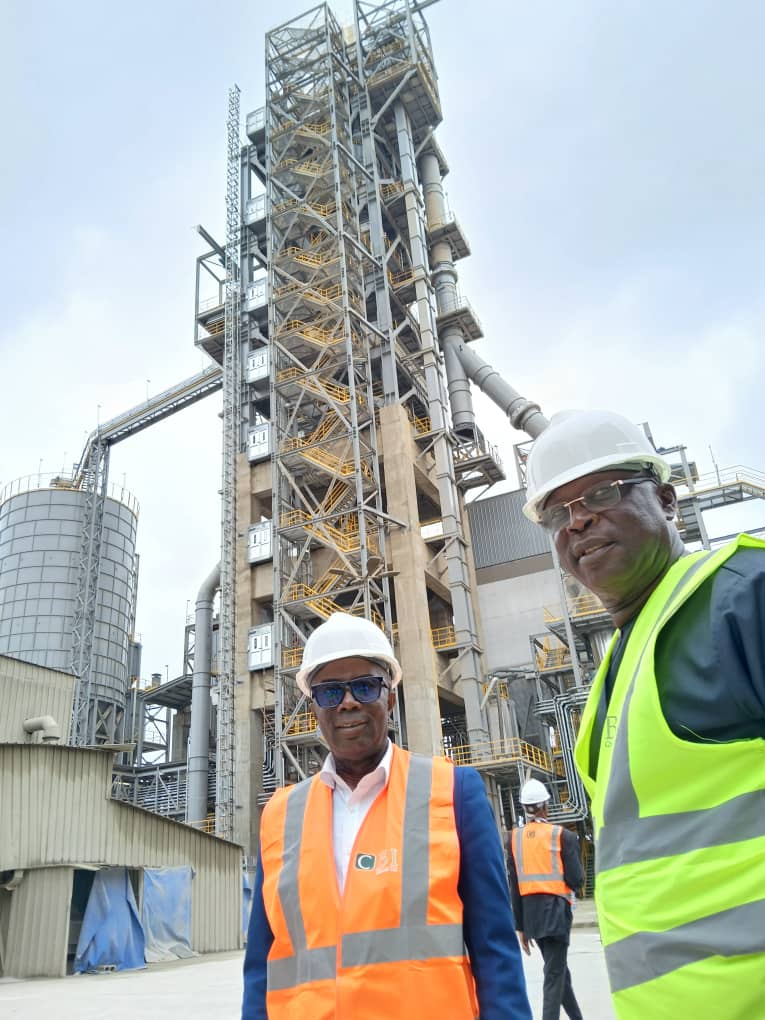

On April 23, 2025, a delegation from the Institution of Engineering and Technology, Ghana (IET-GH), led by its President, Engr. Henry Kwadwo Boateng, paid a working visit to CBI Ghana Limited.

The purpose of the visit was to familiarise themselves with the company’s operations and to tour its newly commissioned Limestone Calcined Clay Cement (LC3) production plant and advanced laboratory facility.

Strategic Sustainability Investment

During the visit, IET-GH held productive discussions with the management team of CBI Supercem, focusing on the strategic vision behind the company’s $100 million investment in LC3 technology.

CBI Ghana’s Managing Director, Frederick Albrecht, underscored the company’s commitment to sustainability, pointing out that Ghana is currently the largest clinker importer in the sub-region.

He explained how the use of local raw materials in LC3 production not only reduces the carbon footprint but also supports job creation across the supply chain.

The discussion included Peter Dickson (Quality and Process), Kobby Adams (Commercial Director), Remi Touvet (Industrial Director), Frederick Albrecht (Managing Director), Engr. Henry Kwadwo Boateng (IET-GH President), Engr. Seth Ayim (Executive Director), Engr. Wonder Salami Davor (President-Elect), and Engr. Mark Nyameche.

IET-GH Applauds CBI’s Innovation

Engr. Boateng commended CBI Ghana for achieving a major milestone in the construction and manufacturing sectors. IET-GH also endorsed Supacem 32.5N, a premium cement product manufactured using LC3 technology.

Understanding LC3

Limestone Calcined Clay Cement (LC3), known as “green cement,” is a sustainable alternative to traditional Portland cement. It is composed of clinker, calcined clay, limestone, and gypsum.

LC3 delivers performance comparable to Ordinary Portland Cement while offering up to a 40% reduction in clinker usage, enhanced durability, and significantly lower CO₂ emissions.

Environmental and Economic Impact

The adoption of LC3 in Ghana presents numerous benefits:

• Reduction of CO₂ emissions by up to 360,000 tons annually

• Creation of new jobs in Tema and Torgorme

• Reduction in clinker imports by 400,000 tonnes

• Local sourcing of raw materials to boost the economy

• Decrease in cargo ship emissions by 60,000 tonnes annually

• Improved cost resilience against currency fluctuations and freight charges

Global Leadership in Standardization

In 2024, Ghana became the first country globally to establish an LC3 standard, permitting cement products with at least 35% clinker.

This initiative enables potential CO₂ savings of 200 kg per tonne of cement. Ghana’s leadership has inspired similar efforts in Togo, Kenya, and across the East African Community, including countries such as Tanzania, Rwanda, Uganda, and South Sudan.

Scientific and Academic Collaboration

CBI’s LC3 project is backed by research from 11 laboratories worldwide, including Ghana’s KNUST, University of Ghana, and BRRI, as well as institutions in Germany, Austria, and Australia.

Supacem LC3 officially launched in Ghana in April 2025, marking a major step forward in sustainable, locally-produced construction materials.

ALSO READ: